Oloa

Fa'aola Taimane Fa'aola Micro Powder

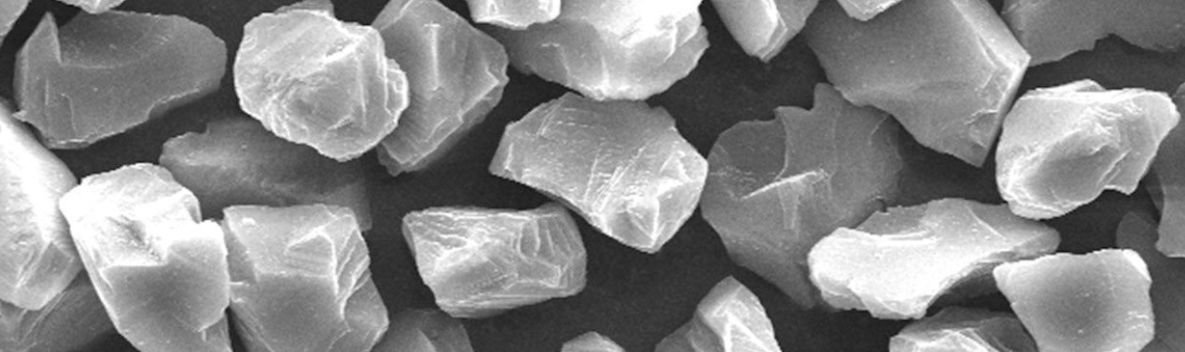

Monocrystalline Diamond Powder

Monocrystalline Diamond Powder o lo'o gaosia mai taimane fa'atosina tasi tioata abrasive fatu e ala i le mamafa o le mamafa, lea e nutimomoia ma fa'aogaina e fa'aaoga ai se faiga fa'apitoa mo mea e sili ona faigata. O ona vaega ninii o lo'o taofia ai le tulaga tioata tasi o taimane tioata tasi.

| Fa'amatalaga | D50 (μm) | Fa'amatalaga | D50 (μm) |

| 0-0.05 | 0.05 | 5-10 | 6.5 |

| 0-0.08 | 0.08 | 6-12 | 8.5 |

| 0-0.1 | 0.1 | 8-12 | 10 |

| 0-0.25 | 0.2 | 8-16 | 12 |

| 0-0.5 | 0.3 | 10-20 | 15 |

| 0-1 | 0.5 | 15-25 | 18 |

| 0.5-1.5 | 0.8 | 20-30 | 22 |

| 0-2 | 1 | 20-40 | 26 |

| 1-2 | 1.4 | 30-40 | 30 |

| 1-3 | 1.8 | 40-60 | 40 |

| 2-4 | 2.5 | 50-70 | 50 |

| 3-6 | 3.5 | 60-80 | 60 |

| 4-8 | 5 |

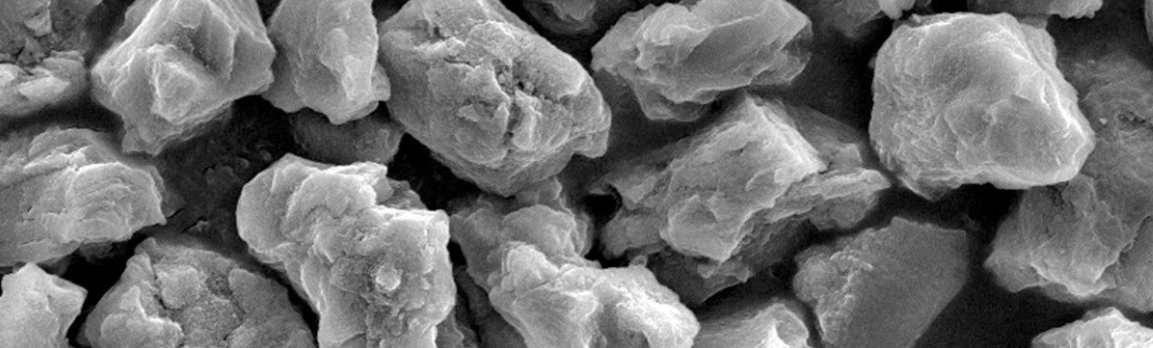

Polycrystalline Diamond Powder

Polycrystalline taimane pauta o micron ma sub-micron vaega polycrystalline e aofia ai fatu taimane ma le lautele o le 5 ~ 10nm fusia e ala unsaturated noataga. O totonu e isotropic ma e leai se vaeluaga. E maualuga le malosi. Ona o lona fausaga tulaga ese, e masani ona faʻaaogaina mo le oloina ma faʻamalo mea semiconductor, faʻamaʻi saʻo, ma isi.

Ole lapopoa ole taimane micro pauta o lo'o i lalo:

Uiga o oloa

-Oversize aveese atoa

-PSD vaapiapi

-O le mama i luga e mafai ona oʻo atu i le maualuga o le ppm

-Ta'apeina tulaga ese

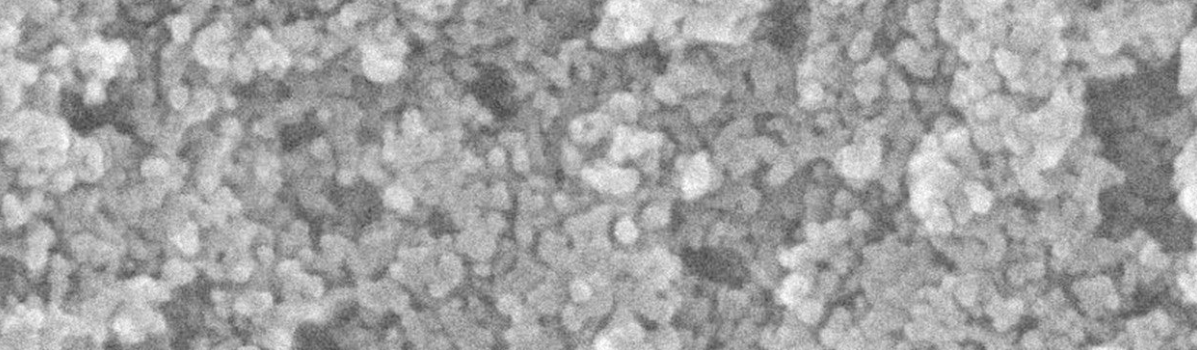

Nano Diamond Powder

Nano taimane pauta ua faia i tioata laiti i lalo o le 20 nanometer, o le tulaga detonative faʻapitoa e maua ai le taimane faʻapolofesa ma vaega galue malosi i luga o le fogaeleele, o lona vaega faʻapitoa e faʻateleina i le tasi faasologa o le tele e faʻatusatusa i le taimane monocrystalline. O lenei oloa e le gata o loʻo i ai le sili ona lelei ma le faʻafefe o le taimane, ae o loʻo i ai foi uiga fou o mea faʻaoga nano.

| Tele | ND50 | ND80 | ND100 | ND120 | ND150 | ND200 | ND300 | ND500 | ND800 |

| D50(nm) | 45-55 | 75-85 | 90-110 | 110-130 | 140-160 | 180-220 | 280-320 | 450-550 | 750-850 |

Uiga

Monocrystalline Diamond Powder Application

1. E fetaui lelei mo uaea taimane fa'apipi'iina maualuga maualuga, uili eli taimane eletise, tipi tioata SiC, naifi, mata va'ai mata, ma isi.

2. Talafeagai mo taimane composite laupepa, taimane polycrystalline ma oloa fa'amau fa'amau, oloa fa'amea sima, oloa taimane eletise, ma isi.

3. E talafeagai mo meafaigaluega taimane eletise, uili olo, ma isi mea faʻapitoa e faʻaaogaina mo le faʻaogaina o mea faigata ma mea vaivai.

4. E fetaui lelei mo le oloina saʻo ma le faʻailoina o maʻa sili ona maualuga, tioata, mea faʻaaogaina metallographic, LCD panels, tioata LCD, safaira, laupepa quartz, LED safaira substrates, tioata LCD, mea keramika, ma isi.

Polycrystalline Diamond Powder Applications

1. Manifinifi ma fa'aiila o fafie semiconductor, pei ole SiC wafer ma safaira

2.Surface polesi o mea sima eseese

3.Surface polishing o mea uʻamea, e pei o uʻamea uʻamea, alumini alumini ma isi

Nano Diamond Powder Applications

1. Faila sili ona lelei. E mafai ona o'o atu i le tulaga o le angstrom e aunoa ma ni maosiosia, lea e mafai ona fa'amalieina ai le mana'oga o le fa'aiila.

2. Nano taimane e mafai ona faʻaaogaina e fai ma faʻapipiʻi suauu lubricating. O le felafolafoaʻi faʻafefe o le a suia i le taʻavale feteʻenaʻiga, lea e mafai ona faʻaitiitia ai le faʻalavelave faʻafefe ma faʻaleleia atili ai le faʻatinoga o feteʻenaʻiga ma faʻaumiina ai foi le ola tautua.

3. Fa'apipi'i fa'apipi'i ma su'iina i luga o mea faigaluega eseese, fa'aleleia le fa'aogaina o mea faigaluega, tete'e a'a, a'afiaga faigata ma le ma'a'a o le mea faigaluega.

4. E pei o le pa'u ma palasitika faaopoopo, nano taimane e mafai ona matua faaleleia lona ofuina tetee, puncture tetee, tensile meatotino ma faagesegese foi le faagasologa o le matua.

5. O le mama maualuga nano taimane o le a le mafua ai le teenaina o meaola, i le taimi nei e mafai ona faʻaaogaina lautele i fomaʻi, meaola ma mea faʻalelei ona o lona vaega tele faʻapitoa, malosi malosi adsorption.

Lau Su'esu'ega

Afai ei ai ni au fesili.Faamolemole lagona le saoloto e faʻafesoʻotaʻi i matou.